Blasting Equipment

Home | Blasting Equipment

In the abrasive blasting industry, efficiency and safety stand as paramount concerns. Traditional methods often involve significant time investment and pose risks of injuries. However, the landscape is rapidly evolving with the introduction of modern blasting equipment, which not only revolutionizes the process but also offers a plethora of benefits.

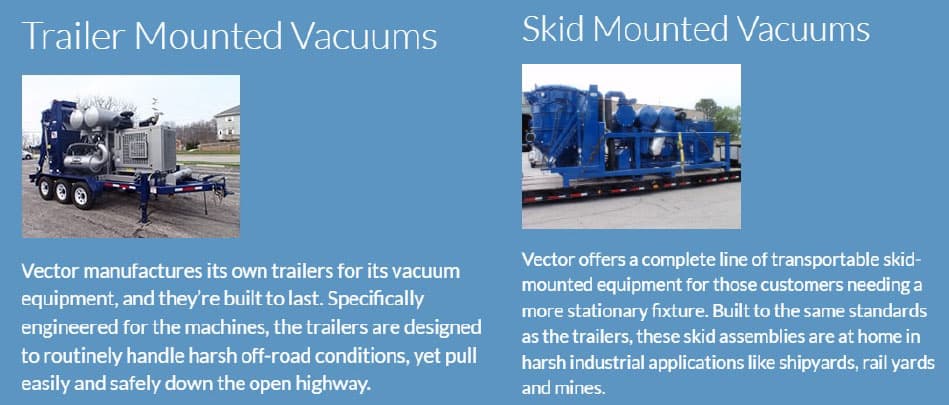

In the abrasive blasting industry, much time is spent and injuries incurred in the process of removal of many tons of abrasive from confined spaces such as tanks, ships, rail cars and underground vaults. The process often involves a lot of pushing and shoveling, wheeling and carrying, and buckets and conveyors. Although a vacuum may be a big investment, it can be a tremendous timesaver and prevent a lot of back injuries and lost-time. If you can’t justify the cost of buying a vacuum, rental from Blast Coat Systems is another option.

Portable blasting systems emerge as versatile solutions in the abrasive blasting realm, catering to diverse needs while minimizing pressure drop. These systems are engineered to handle various media types effectively, ensuring consistent performance across different applications. One of their standout features is their low maintenance design, which translates to minimal downtime and optimal productivity. In addition, their flexibility allows for customization to specific project requirements, offering a tailored approach to blasting operations. Safety remains a top priority with fail-safe valves and controls, providing peace of mind to operators and supervisors alike. If you can’t justify the cost of buying a Blast Pot, rental from Blast Coat Systems is another option.

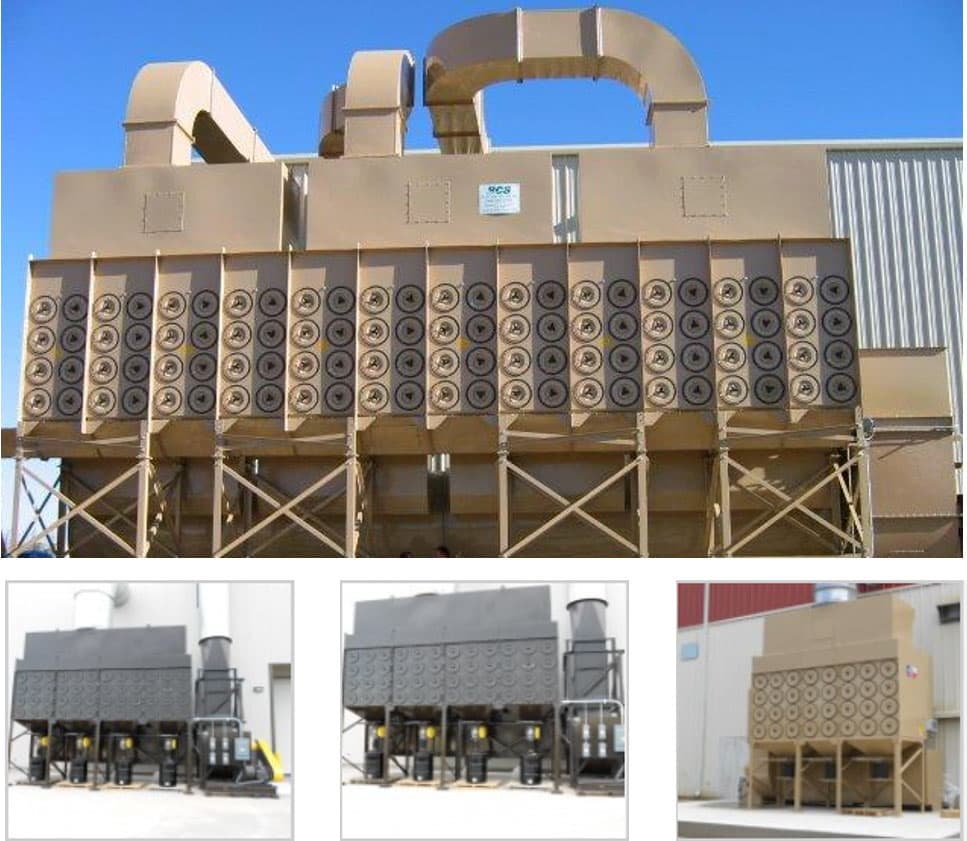

In abrasive blasting operations, managing dust loads is critical for maintaining air quality and safeguarding the health of workers and the environment. Abrasive Blast Systems, LLC (ABS) stationary cartridge-style dust collectors play a pivotal role in this regard, efficiently capturing and containing dust particles. Available in various sizes to accommodate diverse requirements, these collectors ensure optimal airflow, supported by gravity or auger discharge options for seamless operation. Their filtration performance meets HEPA standards, underscoring their effectiveness in preserving air quality and mitigating environmental impact.

Van Air Systems’ Blast Pak PRO sets a new standard for drying solutions in blasting and painting applications. Engineered for maximum portability, these pre-assembled dryers streamline operations in mobile settings. Whether mounted on trucks or trailers, they offer unmatched convenience and efficiency, allowing contractors to optimize their workflow and achieve superior results. With features such as automatic moisture control and robust construction, the Blast Pak PRO ensures consistent drying performance even in challenging environments. If you can’t justify the cost of buying a Compressed Air Dryer, rental from Blast Coat Systems is another option.

Blast Coat Systems, Inc. specializes in designing, fabricating, and installing abrasive blast booths tailored to specific project needs. With over four decades of industry experience, owner John Ulrich and his team excel in delivering high-quality solutions that prioritize safety and efficiency. Whether it’s a basic setup or an intricate configuration, Blast Coat Systems leverages its expertise to create high-production workspaces that meet or exceed client expectations. By upgrading existing facilities or implementing new installations, businesses can transform their operations and stay competitive in the market.

Outdated facilities can hinder productivity and compromise safety in abrasive blasting operations. Blast Coat Systems offers customized solutions to revamp aging blast booths, addressing common issues such as inadequate lighting, inefficient dust collection, and abrasive recovery. Through strategic upgrades and retrofits, work environments are transformed into efficient, high-production facilities that meet the demands of modern industry standards. By investing in these enhancements, businesses can improve workflow efficiency, reduce downtime, and ultimately achieve remarkable gains in productivity and profitability.